Description

Punches and Dies for Tablet Pressing

Classification of Tablet Pressing Punches and Dies

The tablet press punch and die is an indispensable accessory on the tablet pressing machine. It is also a very important task to correctly select the appropriate dies to use. In many tablet pharmaceutical factories, the improper dies cause much lass in some tablet manufacturing factories. Here we will explain such a matter in several aspects.

1.The classification of tableting punches and dies are not exclusive. we can distinguish them according to the different models of tablet machines used, the different materials used to make dies, the different manufacturing standards such as domestic and EU criteria, and the different die shapes.

1.1 According to the different tablet pressing machines, there are single punch tablet press die, rotary tablet press die, basket tablet press dies and tablet compression press die.

1.2 Upon the various manufacturing material, there are alloy steel dies, cemented carbide dies, ceramic dies, chrome-plated, titanium-plated dies. The most common alloy steel materials for Chinese domestic dies are: GCr15, Crl2MoV, CrWuMn, 9Mn2V, 9CrSi. While the imported dies are commonly seen to be made of: A2, O1, S1, S7, PHG.S, PHG-P.

1.3 As the standards differ, there are ZP die(GB12253.90), IPT dies international standard, EU standard dies, and various non-standard special tablet press die and battery ring die.

The steel to craft the tablet punch tools requires careful consideration as it influences tablet quality as well as the overall expenses of the company. Because the equipment wears, the quality of the tablets produced diminishes.

Single-punch tablet press dies and rotary tablet press dies:

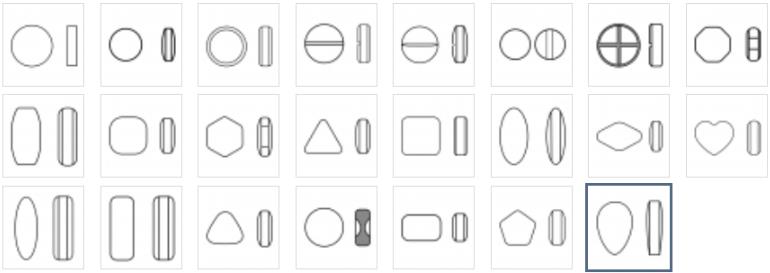

The dies for single punch and rotary tablet pressing machine also vary in their shape, size. The most commonly seen is round shape, and others we call special-shaped dies. All shapes are possible to customized upon requirement.

Usage of Punches and Dies

In tablet production, tablet presses and dies are equipment that directly compresses granular into tablets. Dies are the main consumable spare parts in the tablet pressing process which can be in large quantity need. During the tableting, the axial force generally will be 50-100kN, a great challenge to the service time of dies. So use the dies in a correct and reasonable way ensures the quality of the tablet and prolongs the service life of the spare parts, thereby reducing operating costs.

Precautions During Punches and Dies Usage

(1) A storage room for dies and punches should be set up. The designated person should be responsible for the verification, inspection, maintenance, storage and distribution of the dies. The record should be well kept.

(2) Check the roughness of the dies before and after use. Check whether the mold has curling, missing corners, bursting, or abrasion. Die face with letters engraved should be clean.

(3) In order to prevent the difference in tablet weight, the length of the punch must be consistent. Especially when replacing old dies with new molds. They should be in a good match.

(4) The adjustment of the compression force should be as small as possible, according to the qualified tablet hardness. Do not excessively increase the pressure in pursuit of the harder the tablet. Overpressure does no good to the tablet and the rotary pressing machine.

(5) Assembling and disassembling the punch and dies, follow the manual instruction. (6) After the pressing is finished, the die should be removed in time, wiped clean, wiped with oil to prevent rust.

Cleaning of Punches and Dies

It is recommended to use isopropyl alcohol for cleaning. Clean the dies and wipe them dry, apply anti-rust oil, and store it in a box. Each set of punch and die has its own storage case. Users can also buy an ultrasonic cleaner to automatically clean those spare parts. Soaking in 70℃ degrees RO water, adding alkaline cleaning solution, clean automatically by the ultrasonic cleaner with stainless steel support.

How to measure tablet size to decide the dies?

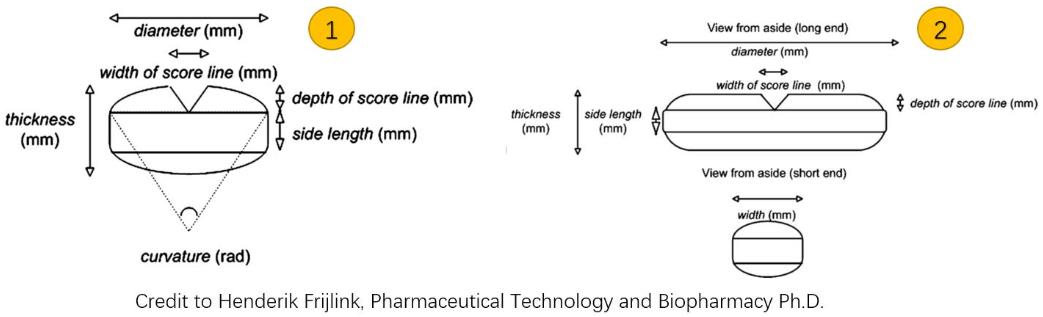

The below photos show a general idea of the data and size needed to determine a tablet size. For us tablet press machine supplier, we have our own vivid 3D dimension tools to design. For the buyers, it doesn’t require such detailed data. Provide us with shape, max. length, minor axis size, thickness and etc, we will be able to design a draft for both sides to confirm. There are so many shapes and sizes of the tablet that can be designed. Please checking with us.

How to choose the right punches and dies?

Tablet Compression Tooling Equipment

The punches and dies in tablet compression tooling equipment is one of the crucial facts to consider when it comes to tablet making. Poorly designed tablet press tooling will result in a bad product that costs great loss for the company. Thus good and enough communication between machine supplier and tablet manufacturer much matters.

Tablet production speaking, the process will be easier, more efficient if the material is easy to compress, coating and package. Marketing speaking, the tablets should be attractive to buyers to build up customers’ recognition and loyalty and trust.

After communication, the press tooling supplier get a clear idea of the nature of the tablets asked by the manufacturer. They should be able to provide details of the correct tools required. Details include shape, hardness, and cup size. The discussion group might involve the R&D team, engineering team, marketing department, production, and packaging workshop.

Tablet Embossing or not?

A logo on the tablet do make it more appealing and establish a product identity which is very good for marketing. But embossing does not fit all tablets, manufacturers should consider the potential problem caused by engraving. Those can be like weakening the surface of the tablet, leading to erosion, and picking and sticking. Also engraving might weaken the tablet tooling. Thus if the tablet is prone to erosion, it is better to avoid embossing.

Tablet Pressing Characteristics

There are many aspects to consider for a new tablet product. In formulation, manufacturer need to consider compression, pH factor, abrasive and stickiness. In the matter of digestion and release, release time, chewable or not, dissolution is the topics. There are more to talk such as tablet coating, tablet identification, targeted consumers, packages.

The quality of a set of punch and die is hard to tell by just looking at the appearance. Users can only tell the difference after a period of usage on tablet pressing machines.

We accept customized orders for tablet pressing punches and dies, using the latest CAD/CAM technology, fine quality alloy steel, excellent heat treatment technology, and scientific testing methods to produce various tablet press die. Pricing is available to contact us.

Other related tablet machines

Rotary tablet press machine: https://www.jspharma.net/category/rotary-tablet-press

Tablet dust vacuum: https://www.jspharma.net/tablet-dust-vacuum/