Description

Capsule Inspection Machine| Inspecting Capsule and Pill

Capsule Inspection Machine Description

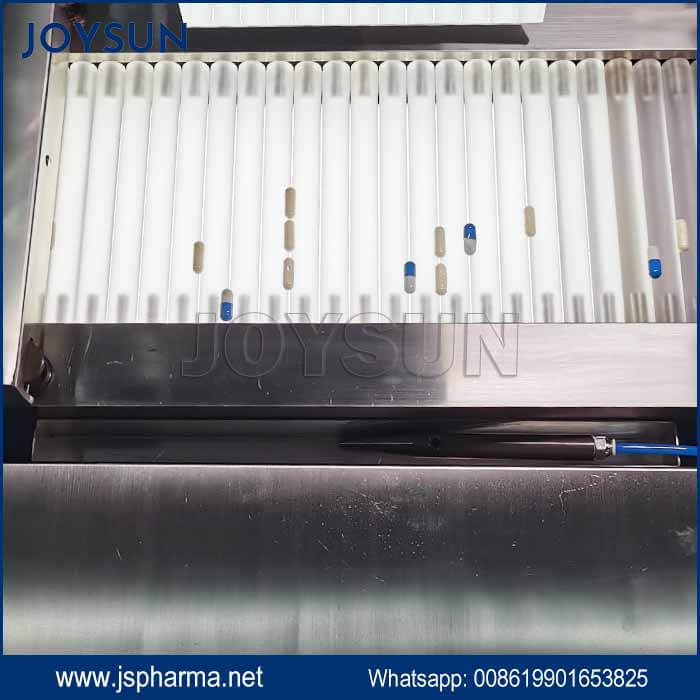

The capsule Inspection Machine is equipment to inspect and pick out disqualified capsules, consisting of an inspection light and rolling conveyor. It is suitable for capsules, softgel and tablets.

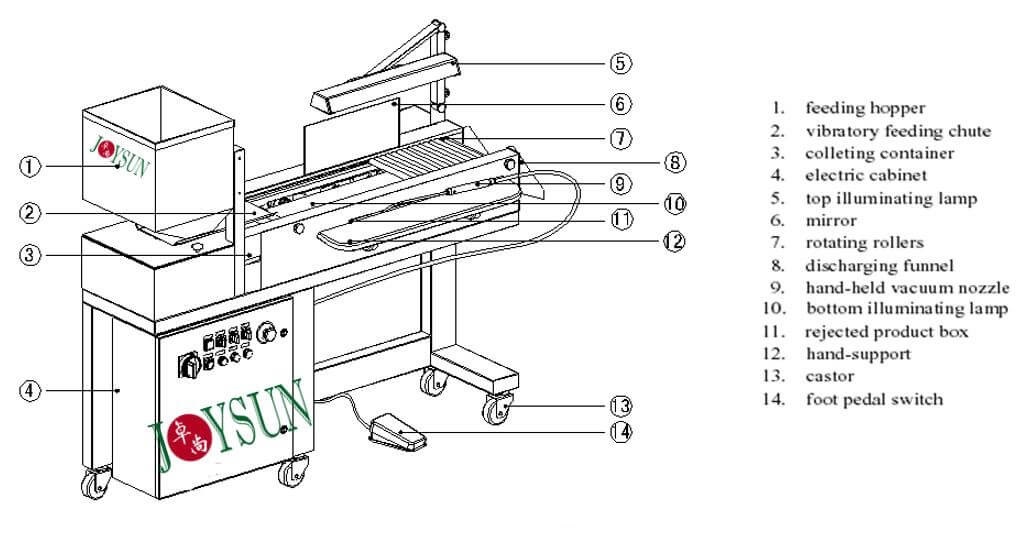

Capsule Inspection Conveyor Structure

Brief Usage

Firstly, we load the capsule into a feeding hopper installed on top of the inspection machine. Capsule/tablets will fall down into a vibratory chute where a perforated screen eliminates coarse dust and chips from the surface of capsules. A built-in container is there to collect the dust. Then capsules will spread onto the conveyor, not accumulate onto each other. The conveyor rolls forward as well as self-rotates to toss up capsules and tablets. Thus the worker can have a clear view of the capsules from different angles. A magnifier on top of the conveyor is adjustable for a bigger and better view. What’s more the inspection roller’s speed is adjustable.

Capsule Inspection Machine Demo Video

Capsule Inspection Machine Technical Parameter

| Application: | Capsules, Tablets and Softgel |

| Inspection capacity: | up to 120,000 capsules/h or 50 kg tablets/h, depending on product |

| Min. Tablet thickness: | 3mm |

| Hopper volume: | 30L,or 60L |

| Working height: | 830 mm |

| Power supply: | 220V/50Hz/Single phase;or 110V/60Hz/single phase |

| Power consumption: | 0.5 kW |

| Compressed air pressure: | 6 bar |

| Compressed air connection: | ø8 mm |

| Overall dimensions: | 1400 x 650 x 1250 mm |

| Machine weight: | 125 kg |

Capsule Inspection Table Features

The rotation speed and inspection speed of the capsule/tablet are variably adjustable.

No hidden corners and blind areas in the inspection stage.

Inspection rollers are made from GMP-approved transparent high-density polymers.

Empty capsules, halves, and chips are often separated automatically with a vacuum unit installed on the inspection belt before the inspection stage.

Defective capsules or tablets can be eliminated by the operator with a flexible handheld vacuum nozzle.

Foot pedal switch to prevent the conveyor belt at any time. While the foot pedal is pressed, the product keeps rotating on the rotating roller at a separately adjustable speed.

The lighting source from the top and underneath for illuminating the inspection stage is a non-flashed fluorescent lamp. Fatigue of the vision can be reduced.

For cleaning purposes, the machine is often completely dismantled with no tools within a couple of minutes. Easy to clean, no cross-contamination risk.

Capsule Inspection Machine Operation Guide

● Turn on the power switch

● Release emergency stop

● Place the collecting container under the vibratory feeding chute

● Place the rejected capsule box

● Place the capsule receiving barrel under the discharging funnel

● Load capsules into the feeding hopper

● Turn on the illuminating lamp

● Start and run the capsule inspection table

● Vibratory feeding speed setup

● Conveyor forwarder speed setup

● Rotating roller speed setup

● Adjust compressed air as per product weight to make sure the hand-held vacuum pen can pick up capsules conveniently and easily.

Tablet Inspection Machine Cleaning

1. After working for a long time, shall clean the machine capsule contact parts, such as feed hopper, vibratory feeding chute, rollers, roller belt, vacuum nozzle, etc.

2. When the change to another type of capsules or tablets, types of capsule product, need to clean the inspection table.

3. After the machine is idle for a long time, before starting it again, shall clean it.

4. When cleaning the machine, shall take apart above mentioned contacting parts and then use neutral detergent or alcohol or clean water and a glabrous soft cloth to clean these parts.

5. For cleaning other parts, use a soft cloth with alcohol to clean the surface.

Tablet Inspection Machine Regular Inspection & Maintenance

1. After the inspection machine works for 500 hours, open the motor box to inspect the motor, and gearbox (reducer). Inspect the fixing bolts of the vibratory feeding chute. Inspect the guiding rail, conveying belt, and friction belt. Inspect bearing. Fasten the bolts, or replace new parts if necessary.

2. The transmission parts are designed for free maintenance; no need to add lubricating oil often. After the inspection machine works for 2000 hours, a whole inspection & maintenance to the transmission parts and change of the lubricating oil for the gearbox.

Caution: any maintenance or repair shall be carried out by a qualified technician or engineer.

Autoamtic Visual Capsule Inspection Machine for Optional