Description

Powder Vacuum Loader|Vacuum Conveyor|Pneumatic Conveyor

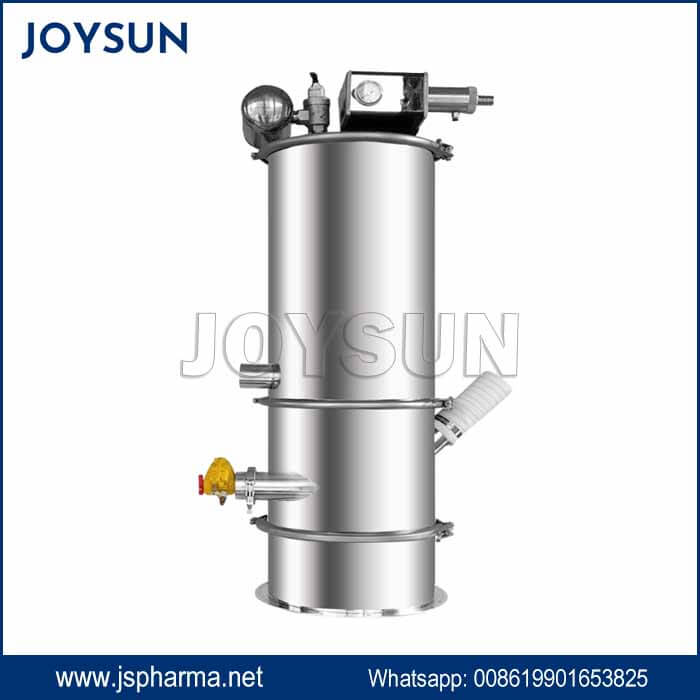

Powder Vacuum Loader Description

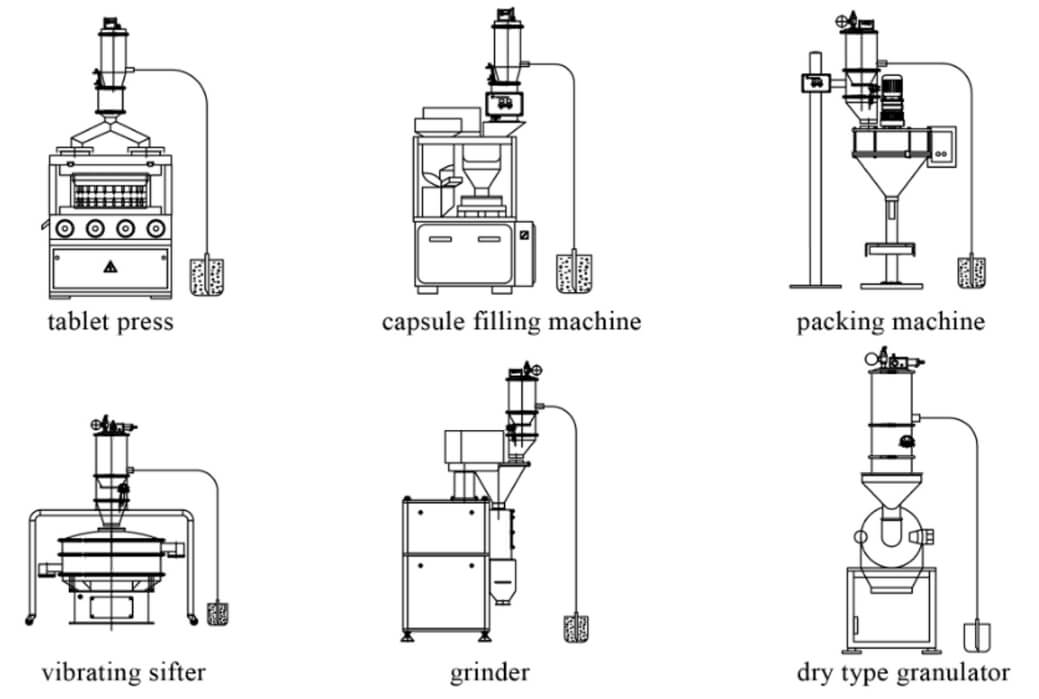

Powder vacuum loader also commonly known as a vacuum conveyor, pneumatic conveyor (vacuum type), it is a device for vacuum conveying powdery materials, granular materials, powder and granular mixtures, and other materials. The vacuum feeding machine can automatically transport various materials to the hoppers of silos, packaging machines, injection molding machines, crushers and other equipment. It can also directly transport the materials to be mixed into the mixer, reducing the labor intensity of workers and solving the problem of This eliminates problems such as dust spillage when adding materials. It’s an effective equipment for pharmaceutical and food factories to pass GMP certification and promote clean and efficient production.

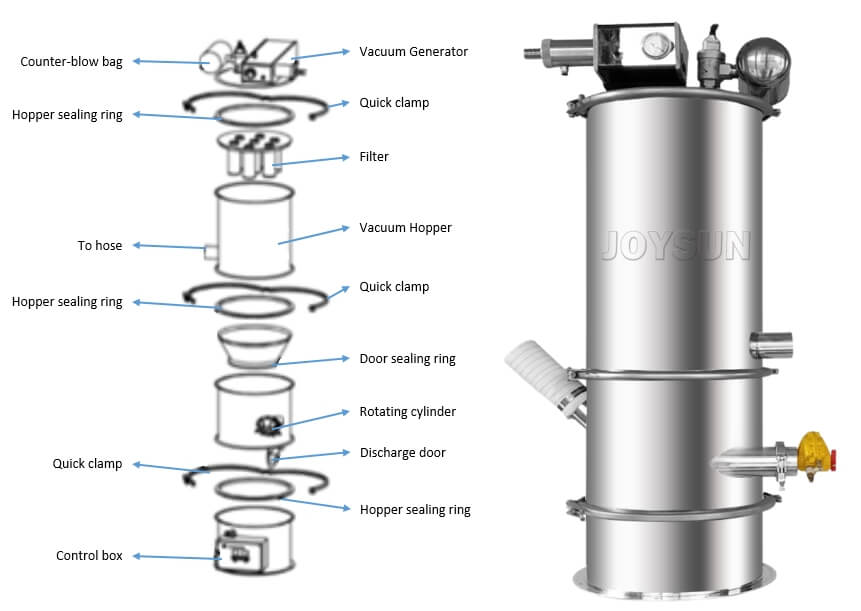

Vacuum Conveyor Structure

Powder vacuum loader consists of a vacuum pump (no oil, no water), a vacuum hopper, a filter (with polyester film filter, PE filter, 316L stainless steel filter, or titanium filter to choose from), and a compressed counter-blow device, pneumatic discharge door device, automatic material level control device, stainless steel suction nozzle, conveying hose, etc. The entire system is reasonably designed and beautifully manufactured.

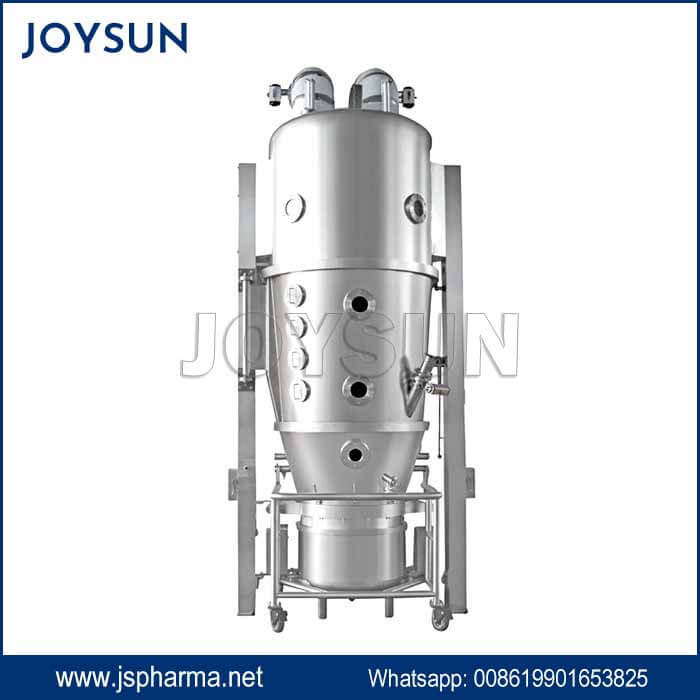

Vacuum Loader for Tablet

Vacuum Loader for Softgel Capsules

Vacuum Loader for Hard Capsules

Principle of Vacuum Conveyor Working

The vacuum loader also known as vacuum feeder, uses a vacuum pump to evacuate air, so that the inlet of the suction nozzle and the entire system are in a certain vacuum state. The powder and granular materials are sucked into the nozzle along with the outside air to form a material airflow, which passes through the suction pipe to reach the hopper, where the air and material are separated. The separated materials enter the receiving equipment. Feeding and discharging are completed by the continuous opening and closing of the pneumatic three-way valve, and the opening and closing of the pneumatic three-way valve is well controlled cabinet.

The vacuum feeder is equipped with a compressed air counter-blowing device. Each time the material is discharged, the compressed air pulses counter-blow the filter to pad off the powder left in the filters. This ensures a normal operation of the suction.

For the vacuum feeder with material level control, the material in the hopper of the receiving device is automatically charged by the material level controller.

When the hopper of the receiving device is higher than a certain position, the vacuum loader stops feeding; When the material level is low at a certain position, the vacuum feeder automatically starts to complete the feeding of the receiving equipment.