Description

Automatic Capsule Filling Machine China Top Quality

Automatic Capsule Filling Machine Reviews

Joysun Automatic Capsule Filling Machine is a perfect upgrading alternative for the Semi-Automatic Capsule Filling Machine. The prototype of our newly invented liquid capsule filler. It has automatic functions including capsule feeding, capsule body-cap separating, powder filling, non-filled capsule rejecting, capsule auto-locking, closing, and gel capsule discharging. One of the popular types among encapsulation machines. We have a wide range of hard gel capsule fillers with various outputs from 12,000 capsules per hour to over 150,000caps each hour. Or another ultra-fast model: 22,8000 filling capacity. The below video shows ‘how to fill empty capsules with powder’ with our automatic capsule filler.

Ultra-Fast Fully Automatic Capsule Filling Machine

Model: JSCP-3800C

Filling Capacity: 228000pcs per hour

Weight: 2200Kg

Dimension: 1500×1200×2200mm

Power supply: 380/220V/50Hz/60Hz, customized

Total power: 10.5Kw

Filling Pins: 27 holes

Vacuum need: 120m³/h, -0.04-0.08Mpa

Dust collector: 24.5Kpa, 210m3/h

Air consumption: 7m3/h

Water source: 1000L/H 0.3-0.4Mpa

Operating noise <75DB(A)

Filling percentage: Empty capsule 99.9% Filled capsule 99.8%

Capsule size: 00,0,1,2,3,4,5#, Safety capsule A-E

Filling accuracy: Western medicine ±3% Chinese medicine ±4%

Suitable: Powder, Granule, Pellet, Tablet.

Capsule Filling Machine Demo Video

How to Change Mold of Fully Automatic Capsule Filling Machine

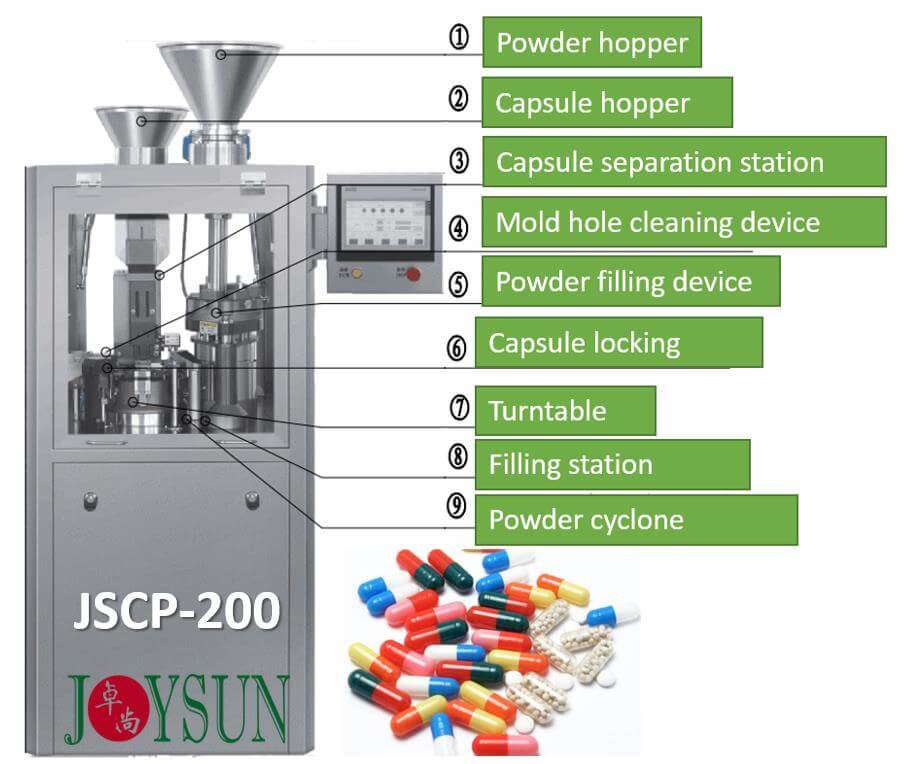

Automatic Capsule Filling Machine Parts Zoom

Hopper for Powder The hopper uses butterfly valve and with a vibration function, is very suitable for powder with poor liquidity. Powder goes down smoothly under vibration.

Clean and installation is easy too.

Capsule Sowing Using guide rail transmission, it has high precision and long service life. The closed design effectively prevents waste capsules and dust from entering. Good stability, orderly sowing and accurate direction adjustment.

New Turntable Turntable is processed and formed in one piece, with a compact structure and no splicing gaps, and has good sealing and easy disassembly; the upper and lower modules move independently, the fully enclosed turntable is free of maintenance, lubrication, maintenance for three years.

Powder Filling Station Modular design and positioning by pins for clamper; No need stop machine to adjust the filling amount, more convenient.

Base of Filling Station The base uses negative pressure design; the powder left here can be sucked back to powder collector. Reduce powder waste and good for recycled to use.

Capsule Discharge Port The capsule discharging port with improve design. No external air source is required when discharges. There is no dust flying during the production process. At the same time, it effectively prevents the capsule from being mechanically pinched at discharge. This part is made of aviation aluminum, strong to use and low wear.

Capsule Locking The capsule locking capsule is flexible to adjust at any time.

New Suction Seat A soft sealing is installed on the suction seat. During the production process, the balance between the lower mold and the suction seat is automatically adjusted. It prevents vacuum leakage and improve the encapsulation rate.

Hole Cleaning Device Using purified compressed air and intermittent air blowing; It solves the problem of medicinal powder sticking to the mold and improves the encapsulation rate.

Powder Recycler Vacuum to collect powder.

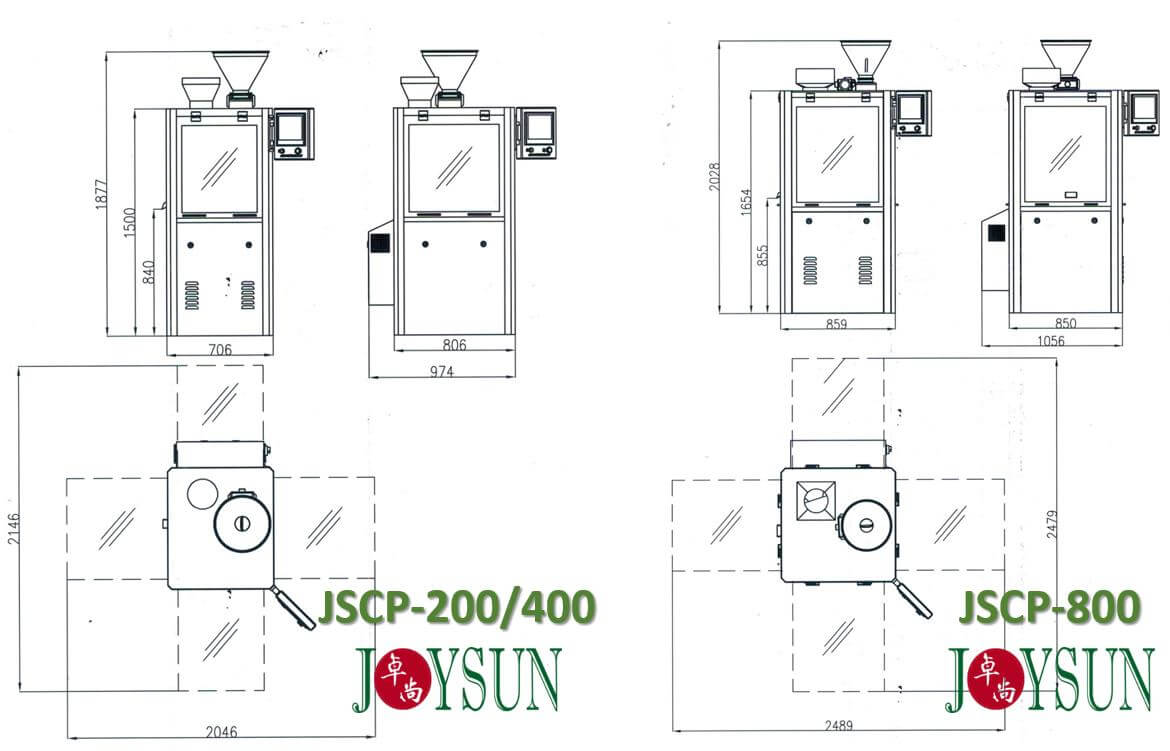

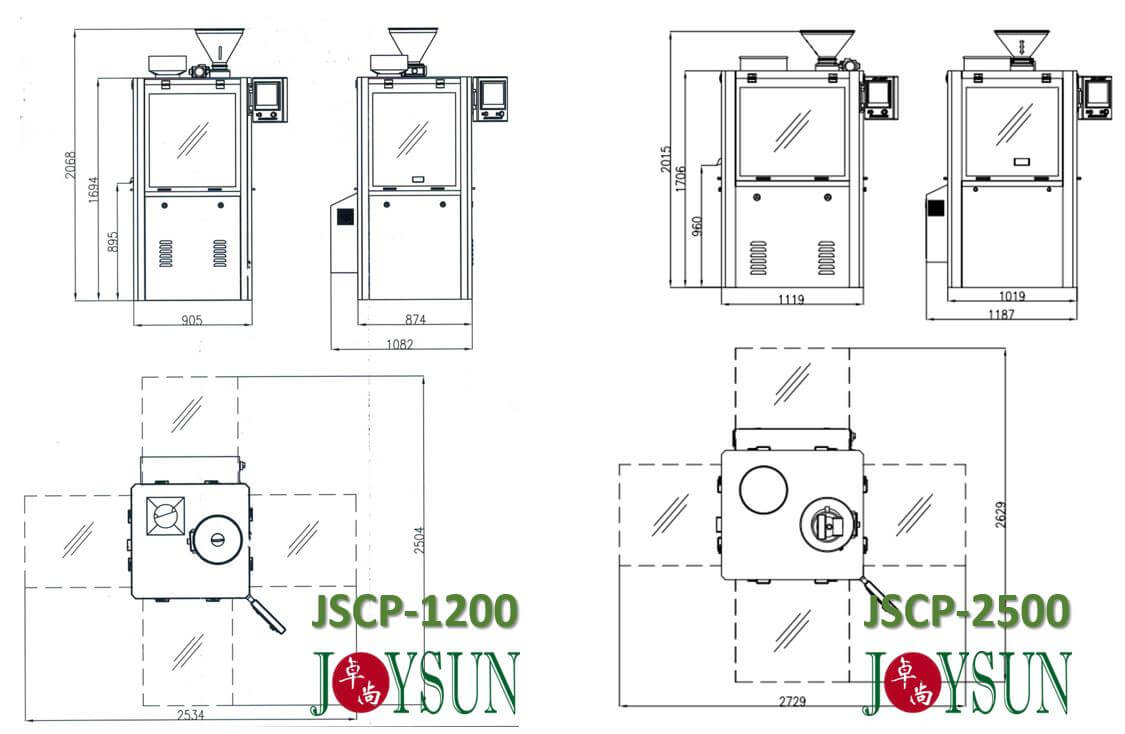

Capsule Machine Layout and View

Let’s take a look at the size and layout of the capsule maker from the top and front. When you buy it, must make sure enough cleanroom space is spared for it. And you also need to consider the operation and maintenance space for the machine during use, debugging, and cleaning.

We hereto make the following quality guarantee to our automatic capsule filling machine:

1. The overall filling machine has strictly followed our company’s quality standard, as well as meeting the requirements of the Pharmaceutical Automatic Capsule Filling Machine JB20025-2004.

2. The machine has passed the inspection of the Zhejiang Packaging Machinery Product Quality Inspection Center, meeting all the requirements for passing the inspection.

3. Strictly follows the IS09001 International Quality Certification System, meeting the requirements of GMP certification.

4. The gel capsule filling and the locking mechanism is produced by our company, pass the acceptance check of FAT, and completely meets the standards of the user requirement specification. (URS)

Automatic Capsule Filler Characteristics:

1. Small in size, light in weight, energy savings, easy to operate and clean.

2. Opening and locking of the capsule can be controlled automatically which is safe and convenient.

3. Equipped with the inching control system, which makes it easy and convenient for cleaning, loading, and unloading upper and lower dies.

4. Equipped with a gate control security system and mechanical failure security system, which provides functions of automatic alarm and shutdown.

5. Automatic alarm and shutdown will be activated when lacking an empty capsule or powder.

6. Rich functions designed on the HMI, including counting and displaying functions during production, and it is able to link with a printer, if needed, for printing information including date of production, lot number, quantity, etc.

7. The plane cams are running in the mode of double rails, where the two axes run out separately. It can improve the operation accuracy and meanwhile eliminate the possibility of collision between the lower die and the dosage disc.

8. The high-precision cam splitter uses the optical dividing head of German Zeiss. The dividing spindle is machined in the CNC all at once, which has ensured accuracy dividing of the turntable and dosage disc while the machine runs fast, thus ensuring the precision of filling. Higher precision of cam splitter /.also provides the machine with long service life.

9. The operating cams are all processed with 20crmoti carburizing and quenching treatment, and then machined in CNC grinding machine all at once, which has ensured the accuracy and unity of the cams and provided a longer service life.

Q1. What can be filled into a capsule?

Powder, granule.

Q2. What is the material of the empty capsule used for this machine?

The material of the empty capsule is the same as regular ones: a two-piece gelatin capsule or HPMC (hydroxypropylmethylcellulose) with cap and body. The capsule size also can refer to the regular empty capsule.

Q3. Can I only buy a capsule filling machine to fill different sizes of empty capsules?

Yes, of course by just changing filling mold; and our machine is designed with easy interchange.

Q4. What is the machine delivery time?

Machine lead time is 35-40days upon receipt of downpayment and technical confirmation. In the case of urgent need, contact us to discuss the possibility of early manufacturing or adjusting dispatch.

Q5. How about the after-service and warranty?

We make the guarantee time 12 months from the machine’s arrival in the buyer’s facility and we have a professional team with an experienced technician to serve abroad and do the best after service to assure the machine’s whole life usage.

Q6. Do you supply all the spare parts related to the machine?

Yes sure. For major and crucial parts of the machine, we cooperate with top-brand suppliers. And we supply all the spare parts which are related to the machine. Feel free to contact us anytime, we will prepare spare parts and arrange transportation as soon as possible.

Q7. How about the payment term?

Thank you for your support and glad to cooperate with your esteemed company. The payment method can be 30% deposit in advance and 70% before shipment.

Q8. How to deliver the machine?

The machine can be sent by both ship and air.

Q9. Machine dispatch package?

By strong seaworthy wood case.

Semi-Automatic Capsule Filling Machine: https://www.jspharma.net/semi-automatic-capsule-filling-machine/

Liquid Capsule Filling Machine: https://www.jspharma.net/automatic-liquid-capsule-filling-machine/