Description

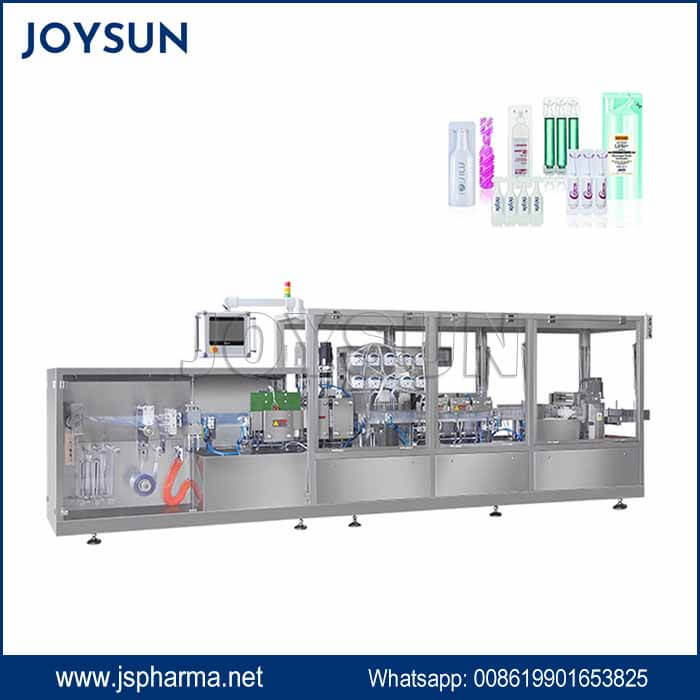

5 Nozzles Liquid Plastic Ampoule Form Fill Seal Machine

5 Nozzles Plastic Ampoule Filling and Sealing Machine Parameter

Monodose liquid Filler/Single-Dose liquid Filler

The Main Technical Parameters

Maximum depth forming: 12 mm

Capacity: approx. 15-25pcs/min/ head; 5heads: approxi100pcs/min;

Filling nozzles: Five filling head filling at the same time

Packaging materials: PET/PE; PVC/PE (0.2 0.4) x 240 mm

The filling capacity:1-50 ml/branch

The total power: 8.5kw

Voltage: 3phase 220V/ 60hz (3phase/380V/50hz); customized upon user’s local system.

Weight: 1200kg

Overall dimensions: 3200*850*1900(mm)

H.S. code/Tariff code: 8422303090

Liquid Form Fill Seal FFS Machine Operation Video

Small Dose Liquid Filler Machine Parts Zoom

Liquid Filled Plastic Bottle or Ampoule Packing Samples

The below table is not limited/Common Shapes

Application:

This type of mono-dose liquid filler(or single-dose liquid filling and sealing machine) has a wide range of applications; it can be used in many industries for products like nutrients, beverage, perfume, cream, gel, solution, lotion, pesticides, fertilizer and etc.. Below is a brief list to show, for more info. please contact us to check out the filling possibility.

Performance and Feature:

♦ Imported electrical components are used on the basis of the original model, so the machine runs more stable.

♦ With the rocker-arm operating interface, you can operate easily in any position of the machine.

♦ HC high-speed and high-precision high-end motion controller. Stepless frequency conversion speed control. Servo motor controlled film pulling device.

♦ Human-machine interface. The device and operation are simple.

♦ Automatic unwinding and film slitting. It has a photoelectric positive and negative pattern matching function. The products are exquisite.

♦ To meet the high standard of packaging requirements.

♦ Using an electronic peristaltic pump device. And mechanical pump piston pump control. Easy to adjust.

♦ The filling accuracy is correct. The filling does not leak, not foam, not overflow.

♦ High-quality stainless steel 316L is used in the parts contacted with the medicine. All the machine covers are SUS304 Stainless steel. It meets the GMP standard. The bottom of the bottle is flat and can stand up.