China machines compared with European machines have the following advantages:

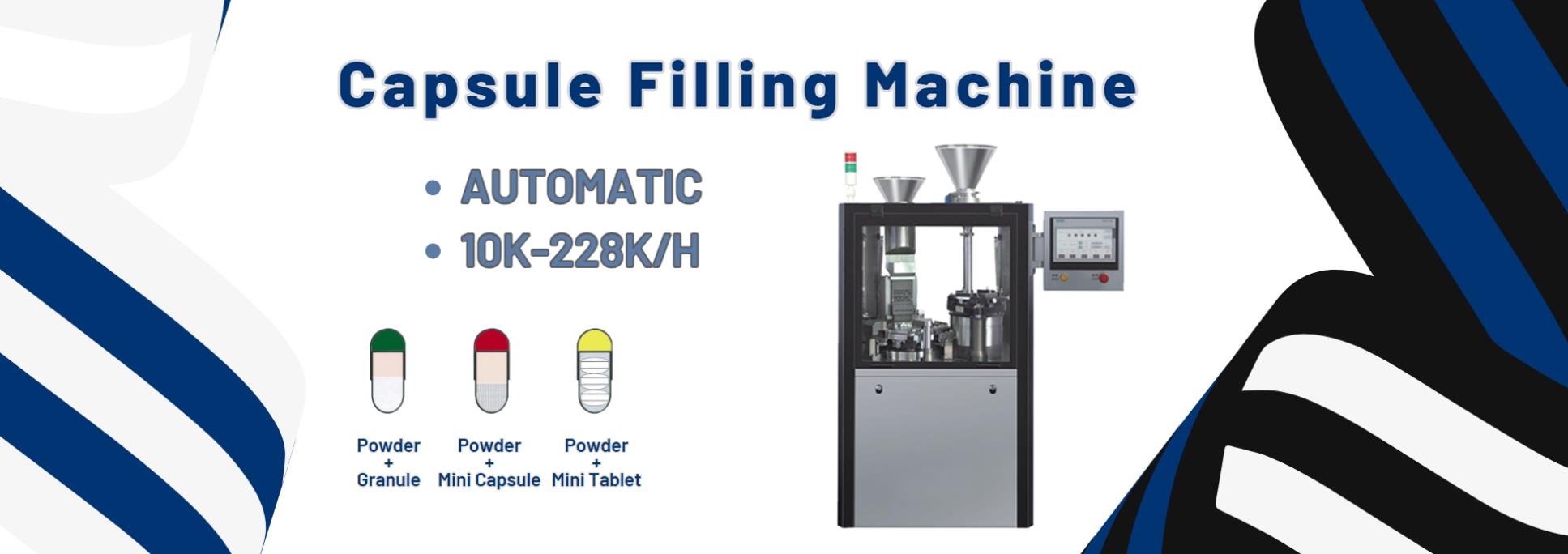

Capsule Filling machines of various capacities are available to choose from. Semi auto capsule filler and fully automatic ones meet different production needs.

Liquid Capsule Filling Machine for filling oil, granules and micro-capsule into normal size empty capsules; Suits for gelatin and HPMC capsules.

Tablet press machine to make tablets and pills. Compression capacity ranges from single punch lab-size tablet press to high-speed rotary tablet press.

PRODUCT GALLERY

Semi-Auto Capsule Filling Machine| Vertical Cap Locking

Dual Feeder Capsule Filling Machine|Double Speed Faster

Automatic Capsule Filling Machine for Sales

Ultra Fast Capsule Filling Machine Fully Automatic

300caps/min Liquid Capsule Filling Machine

Liquid Capsule Banding Machine

1000caps/min Liquid Capsule Filler| Filling&Banding in One

Capsule Mold and Toolings

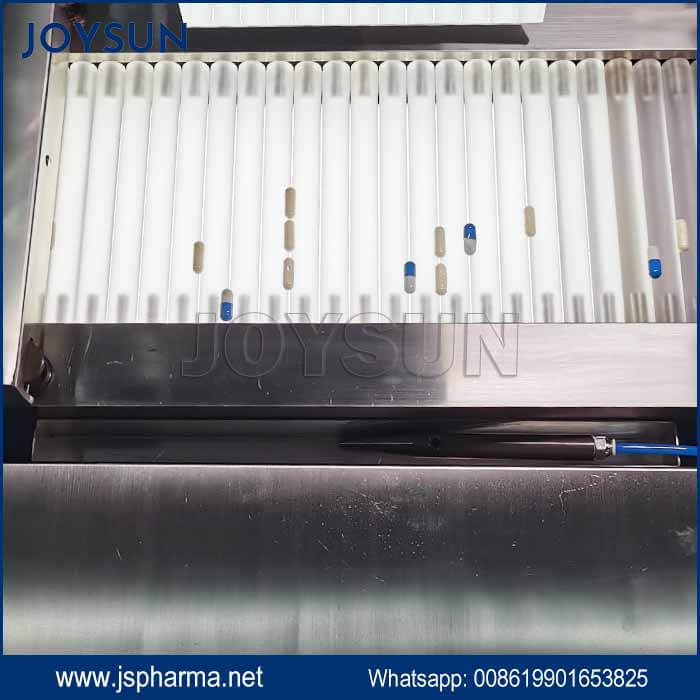

Capsule Inspection Machine| Inspecting Capsule and Pill

Auto Capsule Inspection Machine|Continuous Optical Vision Detecting

Visual Automatic Capsule Inspector

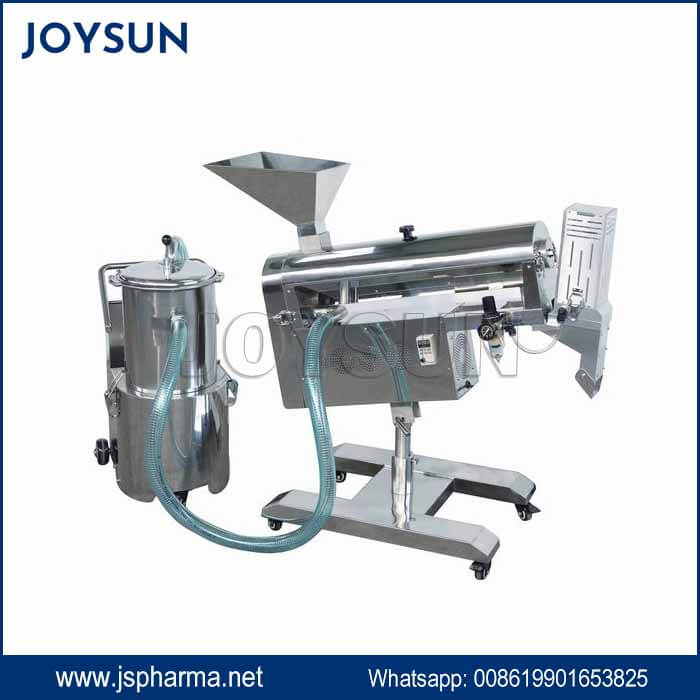

Capsule Polisher|for Semi Auto Capsule Filler

Capsule Polisher|Sorting Function

Capsule Printing Machine| Capsule Shell Printer

Compact Capsule Sorter

Vertical Capsule Polisher

Capsule Deblistering Machine|Separate Capsule from Blister Packing

Capsule Decapsulation Machine|Capsule Segregator

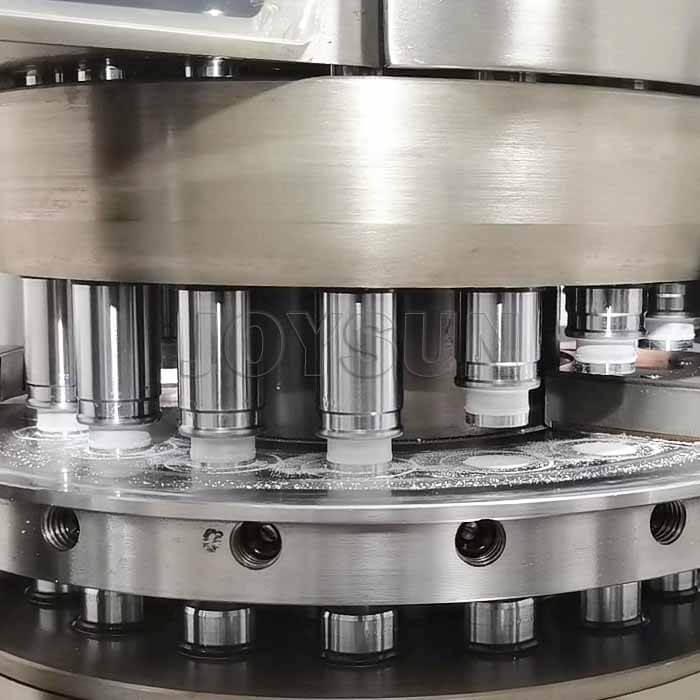

Rotary Tablet Press Machine|Tablet Compression Machine

Tablet Compression Machine Models

Punches and Dies for Tablet Pressing

Anti-Sticking Powder Sprayer for Effervescent Tablet

Tablet Dust Vacuum

Uphill Tablet Deduster

Tablet Pill Printing Machine|Tablet Pill Printer

Tablet Compression Machine|Lab Use Single Punch

Rotary Tablet Press-5 Punches

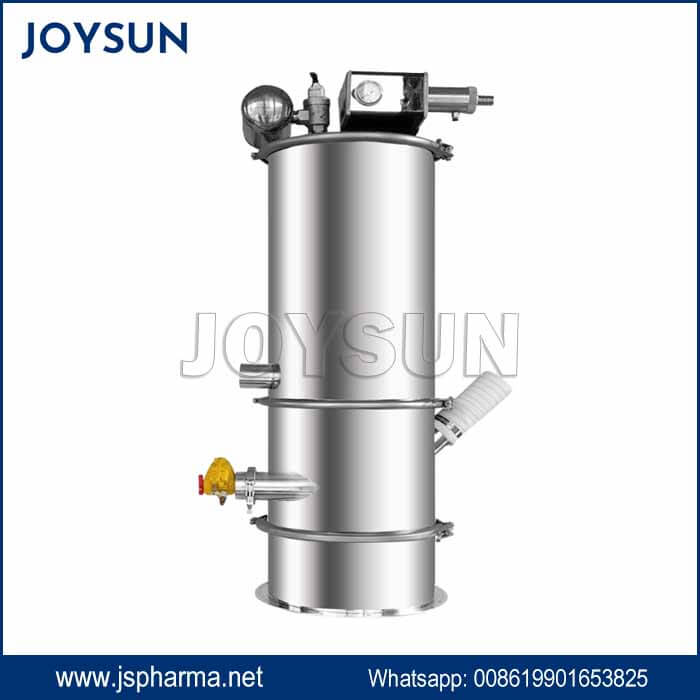

Powder Vacuum Loader

Why Buy Machines from Joysun?

Short Lead Time, can save buyers twice time, most machines take less than one month to finish. A complete turnkey project value of over a million RMB takes less than two months to arrange shipment. Even special customized equipment takes less time to confirm.

Cost Saving. Save buyers twice, triple, or even higher cost when compared with European machines. Some European machines do better than ours. But think of the price saved.

Spare parts are in stock and cost effective. A steady stock of spare parts is ready to dispatch for frequent parts replacement. Even for special parts, our lead times are much shorter.

Quick Response. We can quickly respond to users’ questions via email, online chat, or call. We will establish a chat group to solve the user’s problem. The result is almost the same as ‘onsite’

Customer Acknowledgment. With years of experience exporting, our machines are widely accepted by Asian users, American buyers, and European purchasers. Necessary certificates and documents are available to meet the buying needs.

Renovation and improvement. With the development and improvement of design, crafting, and machining tools, Chinese machines are reliable and stable to use.

Welcome to become our clients or agency.